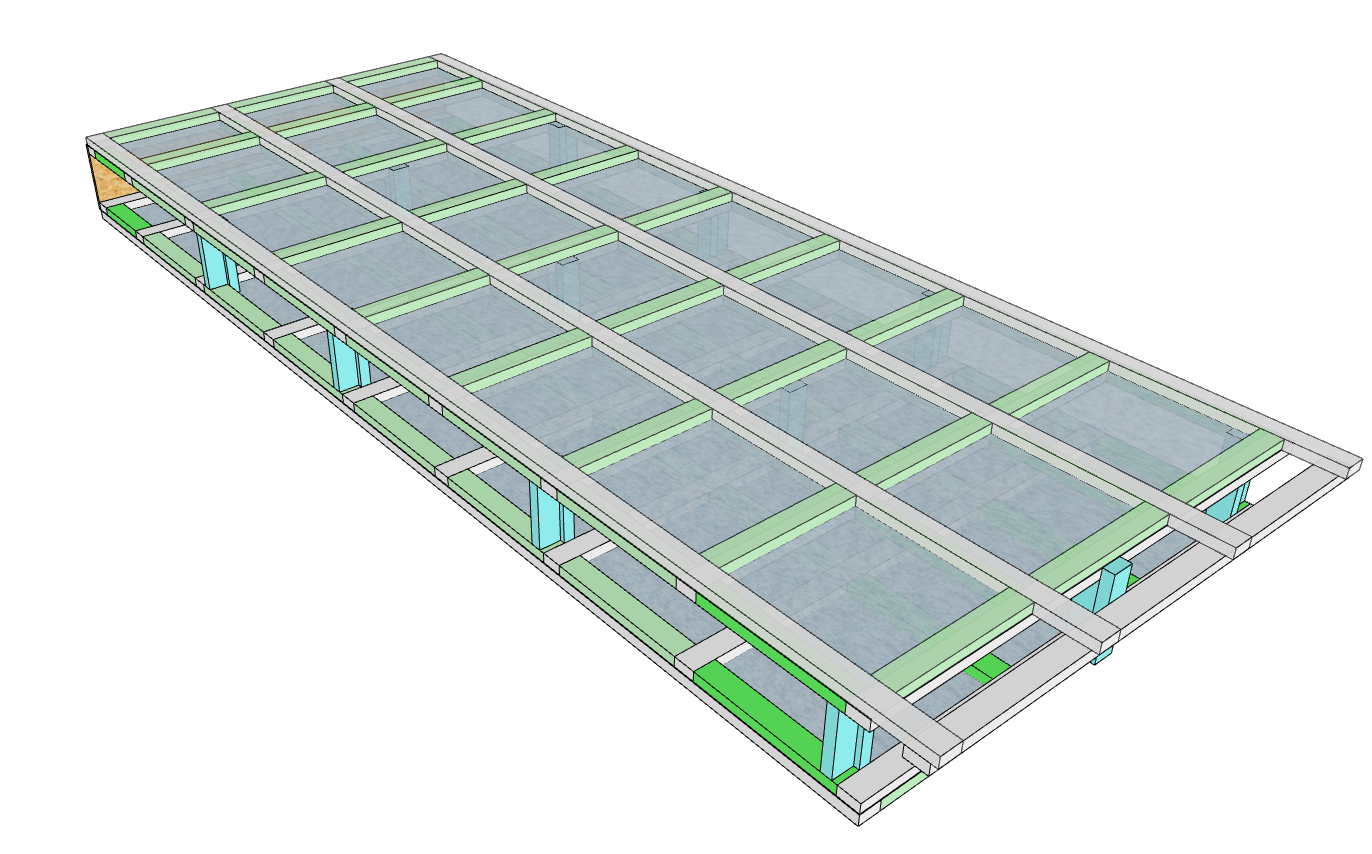

Insulated Panels

One-fill Panels

Quick. Efficient. Low-impact.

We have been manufacturing high precision post-and-beam roundwood frames for 20 years, and for the last 4 years have been developing what we feel is the most environmentally sound method of construction available today.

We engineer the timber frame to provide all necessary structural support which frees us up to use non-structural wall and roof panels. These can be made in our workshop to any depth, and framed out ready to take windows and doors once installed on site.

The panels are filled as one continuous void on-site which eliminates the possibility of any gaps and cold bridging where panels join.

The insulation, panels and frame are all wood fibre, and as such are locking away carbon, giving the possibility of a carbon-negative build to passivhaus standards.

Whether your project is a self-build eco-home, a visitor centre, or a top-spec glamping cabin, Roundwood Design One-fill Panels are the ideal way of providing a low-carbon thermal envelope made from natural materials.

- Vapour permeability ensures longevity -

- UK manufacturing avoids delays and transport-related costs -

- Natural materials mean low environmental impact, and low embodied energy -

Roof and wall insulation are one, minimising cold bridges and eliminating voids, helping to reach passivhaus standards

Internal and external cladding are separate from the insulated panels, allowing customisation and future replacement

Highly vapour-permeable membrane allows moisture to escape naturally

Precision Manufacturing

Quick & Easy On-site

Are you considering a self-build home?

Or looking for a contractor to undertake the whole project from start to finish?

Contact us to discuss your project.